The industrial automation landscape reshapes manufacturing by boosting manufacturing efficiency, safety, and cost-effectiveness. Technologies such as artificial intelligence, robots, and data analytics are driving the shift toward fully autonomous systems. These systems can monitor, adjust, and optimize production in real time. In this article, we’ll explore several key components of industrial automation, including smart factories, automation systems, and equipment, all of which contribute to modern manufacturing’s growth.

Smart Factory: The Future of Manufacturing

A smart factory represents the next step in production. Digital technologies like the Internet of Things (IoT) and artificial intelligence (AI) enable machines to communicate autonomously. This connectivity supports real-time monitoring and decision-making, minimizing downtime and boosting productivity. In smart factories, production systems adapt quickly to demand changes, detect maintenance needs, and optimize resource use.

Industrial Automation System Integrators: Building the Bridge

System integrators play a crucial role in connecting automation systems. They design, build, and configure these systems by combining components like sensors, robotics, and software. Their work ensures smooth operation, enhancing efficiency and reducing operational risks. As factories evolve, integrators use data analytics, AI, and machine learning to improve system performance continuously.

Industrial Automation Software: The Brain of the System

Industrial automation software controls, monitors, and optimizes industrial activities. It ensures timely decision-making by managing machinery and processing real-time data. This software is vital for optimizing workflows, managing resources, and tracking performance data. As industries embrace Industry 4.0, this software evolves, adding features like machine learning and predictive maintenance.

Industrial Automation Systems: Connecting the Dots

Industrial automation systems are responsible for automating production processes. These systems, which include sensors, actuators, and PLCs (Programmable Logic Controllers), monitor and regulate every manufacturing stage. IoT integration enhances data collection and decision-making, improving system functionality. By reducing human error, these systems increase output while improving product consistency and quality.

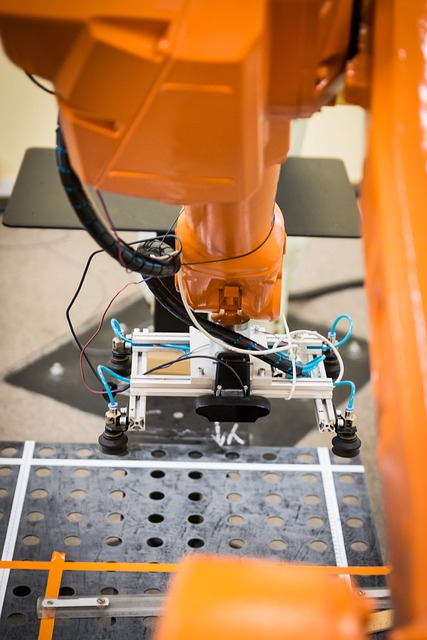

Automation Equipment: The Tools of the Trade

Various technologies now automate tasks previously done by hand. Robotic arms and conveyor systems reduce labour costs and increase production speed. Automation equipment is essential for assembly, inspection, and packing. As automation technology advances, the capabilities of this equipment continue to grow, allowing for more versatile tasks.

Industrial Automation: Revolutionizing Manufacturing

Industrial automation is transforming how machines, production processes, and control systems are managed. From simple control panels to complex networks of automated machinery, automation covers it all. It improves safety, boosts production efficiency, and reduces human error. As AI and robots advance, industrial automation is revolutionizing global manufacturing operations.

Manufacturing Automation: Enhancing Productivity on the Shop Floor

Manufacturing automation aims to boost productivity by streamlining various processes. It can automate entire production lines or specific tasks. Automation reduces operational costs, minimizes downtime, and ensures product consistency. By automating testing, material handling, and assembly, manufacturing cycles are faster, labour costs decrease, and product quality improves.

Conclusion

The future of boosting manufacturing efficiency is driven by the integration of smart factories, automation systems, software, and equipment. Understanding these key elements of industrial automation is vital for companies striving to stay competitive in a digital world. By connecting these components—smart factories, system integrators, automation software, and equipment—businesses can streamline operations, cut costs, and improve quality, paving the way for the next generation of manufacturing.