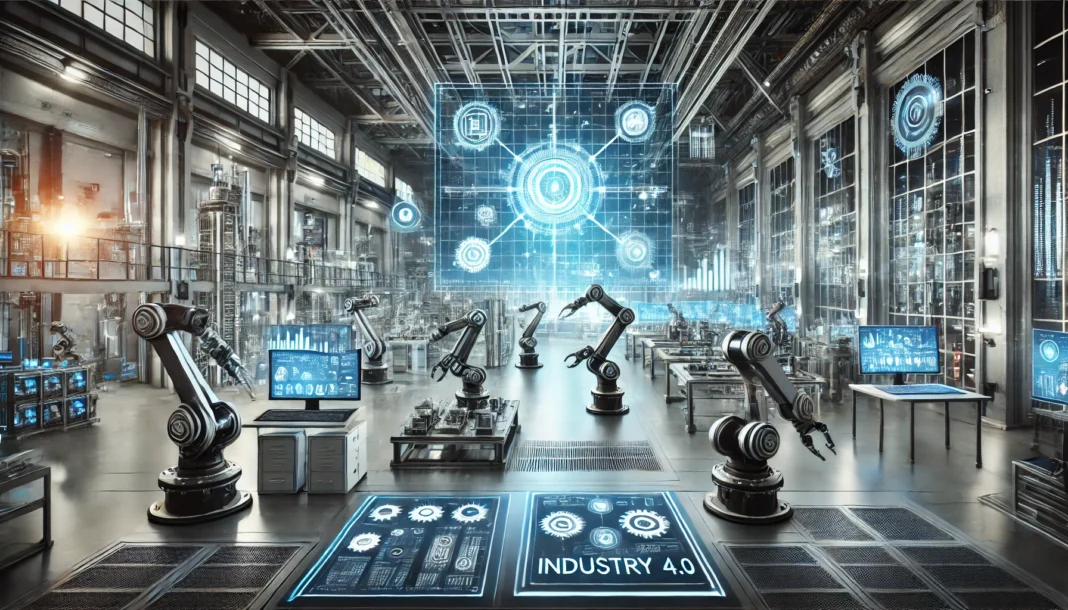

Have you ever felt like the buzz around automation and robotics is everywhere these days? Well, there’s a good reason for it. Automation and robotics are transforming industries at breakneck speed. But what does that mean? How to learn more about it. We created this article to help you learn what an extraordinary book teaches. So, let’s dive into what industrial automation is all about.

Industrial automation uses control systems, like computers or robots, to manage processes and machinery. The goal? Make production faster, more efficient, and less reliant on human intervention. You can think of it as getting machines to take over the boring, repetitive, and dangerous jobs or the tasks we’re honestly happy to give up.

The Role of Robotics in Modern Industry

At the heart of this industrial change is robotics. The machines are designed to do the tasks we set for them but with superhuman precision and reliability. The magic of robotics technology lies in its versatility. Now, robots can weld car parts, assemble electronics, and even carefully package products without getting tired. This consistency means fewer errors and higher quality, ultimately leading to happier customers.

What’s more, robots are now smarter than ever. Thanks to advancements in AI (Artificial Intelligence), these machines aren’t just following pre-set commands. They’re learning, adapting, and even working alongside humans as collaborative robots (cobots). This new breed of robots is all about sharing the workspace safely with humans, adding flexibility to the mix.

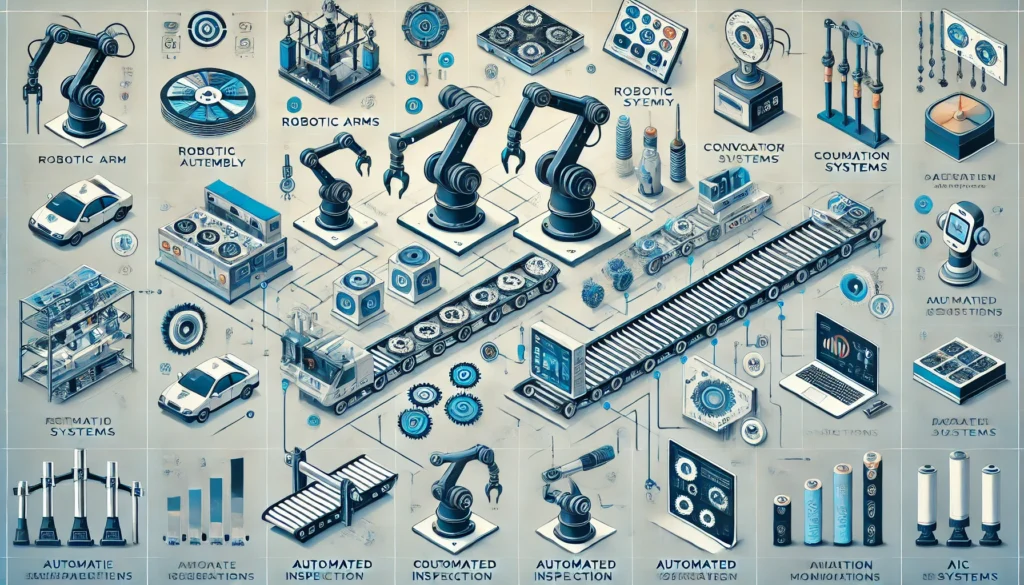

Types of Automated Systems Used in Manufacturing and Other Industries

When it comes to automation, there’s no one-size-fits-all. Automated systems come in different shapes and sizes, each suited for particular tasks. Here are some of the key types you’ll encounter in manufacturing and other industries:

Fixed Automation

This type of automation is designed for high-volume mass production, where the production settings remain constant throughout. It is particularly suitable for tasks that require repetitive operations at a large scale. Imagine an automated production line that continually manufactures identical products. For example, car parts or packaged goods can be purchased without any changes in the configuration. Fixed automation ensures consistent quality and fast throughput, making it ideal for industries focused on efficiency and uniformity.

Programmable Automation

Programmable automation is designed for batch production, allowing easy changes to be made in the production process. This flexibility makes it ideal for producing multiple product versions, such as different models or variations with slight modifications.

Unlike fixed automation, programmable systems can be reprogrammed to handle different tasks, making them particularly useful for industries where products are updated or adjusted frequently. This adaptability is a major advantage in environments where demand changes, helping manufacturers stay responsive without major system overhauls.

Flexible Automation

Flexible automation is highly adaptable, designed to shift between tasks and product types with minimal downtime quickly. This versatility makes it ideal for production environments where product types or configurations change frequently.

Picture a setup that can switch from assembling phones to making smartwatches with a simple adjustment. Flexible automation provides the agility needed for industries dealing with customized or varied product demands, allowing manufacturers to respond swiftly to market changes without significant retooling or interruptions.

Software Automation

Software automation is widely used in IT and business operations to handle repetitive, mundane tasks efficiently. With technologies like Robotics Process Automation (RPA), businesses automate processes like data entry, customer service responses, and financial reporting.

By taking over these repetitive tasks, software automation reduces the risk of human error and allows employees to focus on more creative and strategic work. This leads to increased productivity, better accuracy, and ultimately more innovative output, helping companies streamline their workflows and achieve higher efficiency.

HR Automation

HR automation is using technology to streamline and optimize various human resources processes, such as recruitment, onboarding, payroll, and employee benefits management. By automating these tasks, businesses can significantly speed up workflows, reduce administrative errors, and ensure compliance with regulations.

This, in turn, frees up HR professionals to focus on activities that add more value to the company, such as enhancing employee engagement, fostering a positive work culture, and working on strategic initiatives aimed at improving overall workforce productivity and satisfaction. Automation helps make HR processes more efficient, allowing for a better employee experience.

Service Automation

Service automation involves using chatbots and AI-driven service desks to streamline customer interactions. These tools instantly respond to customer queries, offering 24/7 support without human intervention. This enhances customer satisfaction by providing quick and consistent service and allows businesses to manage high volumes of requests efficiently.

By automating common customer service tasks, companies can focus their human resources on resolving more complex issues and improving overall customer experience. Service automation has become a key component for organizations looking to deliver high-quality customer support at scale.

Supply Chain Automation

Supply chain automation involves using technology to enhance the efficiency of processes ranging from inventory management to logistics and delivery. Automation tools such as autonomous vehicles, drones, and automated warehousing systems transform how goods are handled, stored, and transported. These innovations enable faster and more reliable movement of goods, reducing human errors and increasing overall productivity.

By optimizing tasks such as inventory tracking, order fulfilment, and delivery scheduling, supply chain automation helps businesses reduce costs and meet customer demands more effectively. This leads to a more responsive, agile, and streamlined supply chain from production to the final consumer.

Marketing Automation

Marketing automation involves using technology to streamline and manage marketing activities such as email campaigns, social media postings, and lead management. By leveraging automation tools, marketers can engage with a larger audience more effectively and consistently without spending hours on repetitive manual tasks.

These tools help target specific customer segments, nurture leads, and track campaign performance. As a result, marketing teams can focus on more strategic, creative aspects of campaigns, leading to better customer relationships and more impactful marketing outcomes. Automation ultimately enhances productivity and allows for personalized marketing at scale.

These systems also incorporate PLC (Programmable Logic Controllers), essentially industrial computers that ensure everything runs smoothly by communicating with different machines and sensors.

Key Benefits of Industrial Automation

So, why is there an obsession with industrial automation? Here’s where the magic happens:

Increased Productivity

Automated systems can work continuously, 24/7, without needing breaks, sleep, or rest. This constant operation leads to significantly faster production cycles and ensures that deadlines are met without interruptions.

Unlike human workers who need shifts, automation provides seamless and uninterrupted production, which boosts output and helps meet high demand efficiently. Maintaining an ongoing workflow allows businesses to scale operations and maximize productivity, keeping them competitive in industries where speed and consistency are crucial.

Higher Quality through Automation and Robotics

Automation ensures that machines maintain a consistent level of performance, free from the variability that comes with human factors like fatigue or mood. Since machines don’t experience fluctuations in productivity, they can perform tasks at the same quality level, day in and day out.

This reliability helps reduce defects, minimise waste, and ensure a consistently high product standard. By delivering precision without variation, automated systems produce goods that meet stringent quality requirements, ultimately leading to better customer satisfaction and lower costs associated with errors and rework.

Cost Savings

While the initial investment in automation can be significant, the long-term savings often outweigh these costs. By automating repetitive and labour-intensive tasks, businesses can significantly reduce labour expenses, especially for high-volume production lines.

In addition to reducing direct labour costs, automation minimizes waste and errors, leading to cost savings. The improved efficiency and productivity mean that companies can achieve more with fewer resources, making automation a smart financial decision that pays off over time, especially as it scales up production capabilities.

Enhanced Safety

Automation is crucial in improving workplace safety by taking over hazardous tasks that pose risks to human workers. Robots can handle dangerous operations such as heavy lifting, exposure to toxic substances, or working in extreme environments, which significantly reduces the likelihood of workplace injuries.

By allowing machines to perform these risky jobs, companies can create a safer working environment for their employees. This helps protect workers’ well-being and leads to fewer disruptions and lower costs related to workplace accidents and insurance claims.

How Robotics Technology Is Transforming Manufacturing

Introducing robotics into manufacturing is like bringing in an army of tireless workers who don’t need rest, lunch breaks, or vacations. Autonomous robots can operate independently, perform quality checks, and even adapt to real-time changes in the production line. This agility leads to a new era of smart manufacturing, where systems learn from each other, optimize in real time, and adjust based on demand.

Take, for example, the automotive industry. Here, robots handle welding, painting, and assembling — tasks that require accuracy and repeatability. In food production, robots help packaging products, ensuring hygiene, and maintaining consistent quality. These examples highlight how robotics in industry isn’t just about increased speed; it’s about smarter, adaptable, and quality-driven manufacturing.

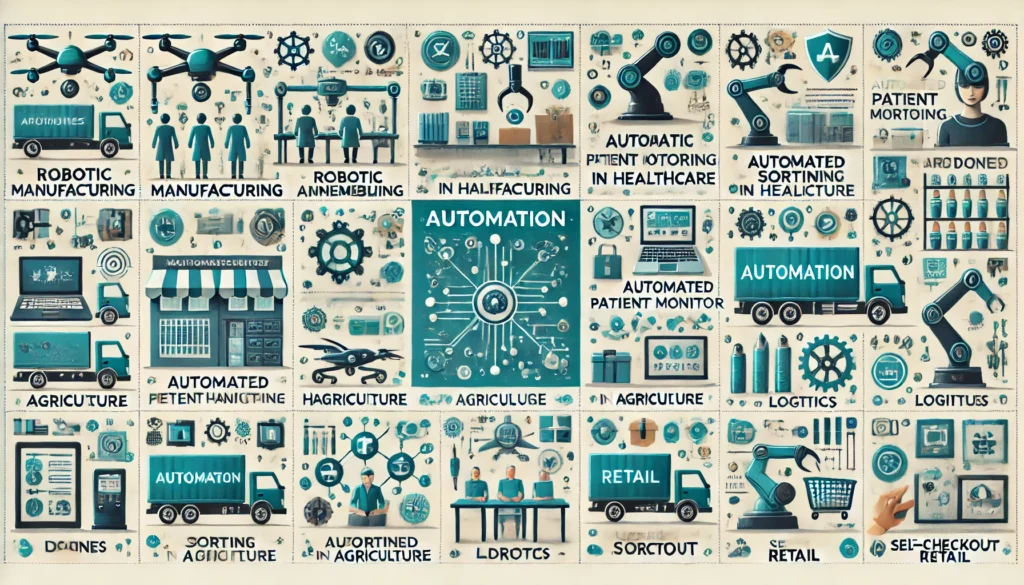

Examples Of Industries Leveraging Automated Systems

Automation isn’t confined to one sector; it’s everywhere:

Automation and Robotics in the Automotive Industry

Robots play a crucial role in welding, painting, and assembling cars in the automotive industry. Their precision ensures that each part is handled accurately, leading to consistent product quality and reducing the chances of errors. This level of automation helps car manufacturers achieve uniformity and efficiency in production, which is essential for meeting industry standards and customer expectations.

Automation and Robotics in Food and Beverage Industry

In the food and beverage industry, automation is essential for ensuring products are packaged safely, hygienically, and consistently. By using automated systems, manufacturers can maintain high cleanliness and efficiency standards, reducing human error and contamination risks. This leads to better product quality, longer shelf life, and increased consumer confidence.

Automation and Robotics in the Pharmaceuticals Industry

In the pharmaceutical industry, robots are crucial for maintaining sterile production environments and ensuring products are free from contamination. Robots reduce human contact by automating tasks like handling chemicals and packaging, thereby minimizing contamination risks and improving product safety. This level of precision is essential for meeting the stringent regulatory standards of the pharmaceutical industry.

Automation and Robotics in Electronics Industry

In the electronics industry, automated production lines greatly enhance the speed and efficiency of assembling gadgets like smartphones and laptops. Automation ensures each component is placed precisely, reducing defects and maintaining consistent product quality. This not only speeds up production but also meets the high standards consumers expect.

Automation and Robotics in the IT & Business Operations Industry

Software automation helps streamline data management, customer service, and report generation. By automating these repetitive tasks, businesses can save time and reduce errors, allowing staff to focus on more strategic and creative work. This efficiency leads to improved productivity and ensures that operations run smoothly.

Automation and Robotics in HR Departments Industry

HR automation tools streamline key functions such as recruitment, payroll, and compliance management. By automating these repetitive tasks, HR departments can operate more efficiently, reduce administrative errors, and ensure a better employee and candidate experience. This also allows HR professionals to focus on strategic initiatives like employee engagement and development, ultimately contributing to a more productive workforce.

Automation and Robotics in the Customer Service Industry

In customer service, automation tools like chatbots and AI-driven service desks provide fast and efficient responses to customer inquiries. This ensures round-the-clock availability, improves response times, and enhances customer satisfaction by offering consistent and reliable support. By handling common questions automatically, businesses can free up human agents to focus on more complex issues, ultimately improving overall service quality.

Automation and Robotics in the Supply Chain & Logistics Industry

Supply chain and logistics automation includes technologies like automated inventory management, autonomous delivery vehicles, and drones. These innovations help streamline the flow of goods, reduce human errors, and increase overall efficiency. By automating tasks like inventory tracking, order fulfilment, and delivery, companies can respond to demand more effectively and ensure a faster, more reliable supply chain.

Everywhere you look, companies use automated production lines to take their efficiency and quality to new levels.

Challenges And Limitations of Industrial Automation

Now, let’s not pretend that automation is all roses and rainbows. There are challenges:

- High Initial Costs: Setting up the infrastructure for automation and robotics can be expensive. The upfront investment includes purchasing advanced equipment and software and integrating new systems. These initial costs can be a significant barrier, especially for smaller businesses. However, the long-term efficiency and cost savings benefits often make automation a worthwhile investment over time.

- Skilled Workforce: Implementing automation requires a skilled workforce to operate, maintain, and repair advanced systems. Technicians with specialized knowledge are essential to ensure that automated processes run smoothly, handle troubleshooting, and optimize the efficiency of these technologies. Without properly trained staff, the potential benefits of automation could be limited due to operational inefficiencies and increased downtime.

- Resistance to Change: Resistance to automation often arises because it is perceived as a threat to jobs. While automation does lead to replacing certain roles, it also creates new opportunities, such as positions in system maintenance, programming, and oversight. These new jobs require different skills and offer growth in areas aligned with technological advancements, making the workforce more adaptable in the long term.

The Future of Robotics and Industrial Automation

The future looks bright for automation and robotics. Imagine factories where Industrial IoT (Internet of Things) links every machine to a central hub. This creates a flow of information that can be analyzed to find ways to boost productivity.

Then there’s Human-Robot Collaboration. We’re entering a phase where robots aren’t replacing people but working alongside them. Imagine robots taking on heavy lifting while humans focus on tasks requiring creativity or problem-solving. This partnership could redefine what an efficient workplace looks like.

How To Implement Industrial Automation in Your Business

If you’re wondering how to bring automation into your own business, here’s a roadmap:

Assess Your Needs

Not every process will benefit from automation. Start by identifying repetitive and time-consuming tasks suitable for machines to take over. These tasks are often the best candidates for automation as they require minimal decision-making and can free human workers to focus on more strategic, high-value activities. By carefully evaluating which processes to automate, businesses can ensure the most efficient use of resources and maximize the benefits of automation.

Set Clear Objectives

Clearly defining your objectives is essential before implementing automation. Whether your goal is faster production, fewer errors, or improved data collection, understanding these needs will guide you in choosing the most appropriate automation system. Having well-defined objectives ensures that the automation strategy aligns with your business priorities and delivers tangible results.

Pilot Before Scaling

Begin by automating a small part of your production line or a single process. This approach allows you to evaluate the benefits, identify and solve any issues, and make necessary adjustments before implementing automation on a larger scale. Piloting helps minimize risks and provides valuable insights, ensuring a smoother and more effective transition.

Train Your Workforce

Training your workforce is essential for a successful automation transition. Employees must understand operating, maintaining, and troubleshooting new automation systems through the top automation courses. Proper training ensures that workers are comfortable with the technology and reduces downtime and errors, leading to a more efficient production process. Investing in employee training helps build confidence, maximizes the benefits of automation, and ensures a smoother transition for everyone involved.

FAQs About Automation and Robotics

What is industrial automation and why is it important?

How do robots contribute to industrial automation?

What are the main types of automated systems used in industry?

How does industrial automation improve productivity?

What industries benefit the most from robotics technology?

What are collaborative robots (cobots) and how do they work?

What are the challenges of implementing automation in manufacturing?

How does automation impact workers’ jobs in the industry?

What is the role of AI in robotics and automation?

How can a business start implementing industrial automation?

Wrapping It Up

Automation and robotics are reshaping how we make, move, and deliver things. You can enter the world of automation by understanding the opportunities and challenges, businesses can tap into these technologies to boost efficiency, improve quality, and remain competitive in an increasingly automated world. The future isn’t just automated; it’s smart, adaptable, and all about working together.