Certainly, modern markets demand maximum efficiency and reduced operational costs. Indeed, automation and robotics now provide solutions for these needs. Specifically, these technologies allow businesses to boost productivity and maintain high-quality standards. Moreover, they lower manual errors and free workers for higher-level tasks. Consequently, industry leaders have embraced robotics to stay ahead in fast-paced environments. In this article, we will explore the best automation companies. Additionally, we will discuss leading robotics innovators driving industrial transformation.

The Evolving Landscape of Automation and Robotics

However, automation involves hardware, electronics, and software to streamline tasks with minimal human intervention. Indeed, the global market has seen rapid growth in robotics solutions. Additionally, modern factories require advanced technologies to maintain cost efficiency and product consistency. Consequently, industry players have focused on collaborative robotics and digital integration. Indeed, these solutions enhance worker safety and overall operational output. Thus, businesses in logistics, manufacturing, and healthcare increasingly rely on automation to remain competitive.

Five Best Automation Companies and Their Robotics Innovations

Several major players drive modern automation trends. Specifically, these corporations design cutting-edge robots, IoT platforms, and industrial control systems. Consequently, their solutions push productivity forward and inspire further research. Below, we examine five leading automation and robotics innovators.

1. ABB

Firstly, ABB is a Swiss-Swedish corporation with expertise in power and automation technologies. They have provided innovative industrial solutions for over a century. Their portfolio includes robotics, electrical equipment, and advanced automation software. Moreover, ABB serves sectors such as automotive, electronics, and metal fabrication.

However, ABB’s robots cover diverse payload capacities, ranging from small tabletop units to heavy-duty arms. Their RobotWare and RobotStudio suites enable offline programming and real-time simulations. Additionally, ABB’s YuMi cobots emphasize safe collaboration and precise assembly tasks. The ABB Ability™ platform unifies IoT analytics with cloud-based services.

Therefore, ABB stands as a leading partner for businesses seeking digital transformations. Specifically, their combination of powerful hardware and intuitive software facilitates seamless production line integration. As a result, many industries rely on ABB to accelerate automation initiatives.

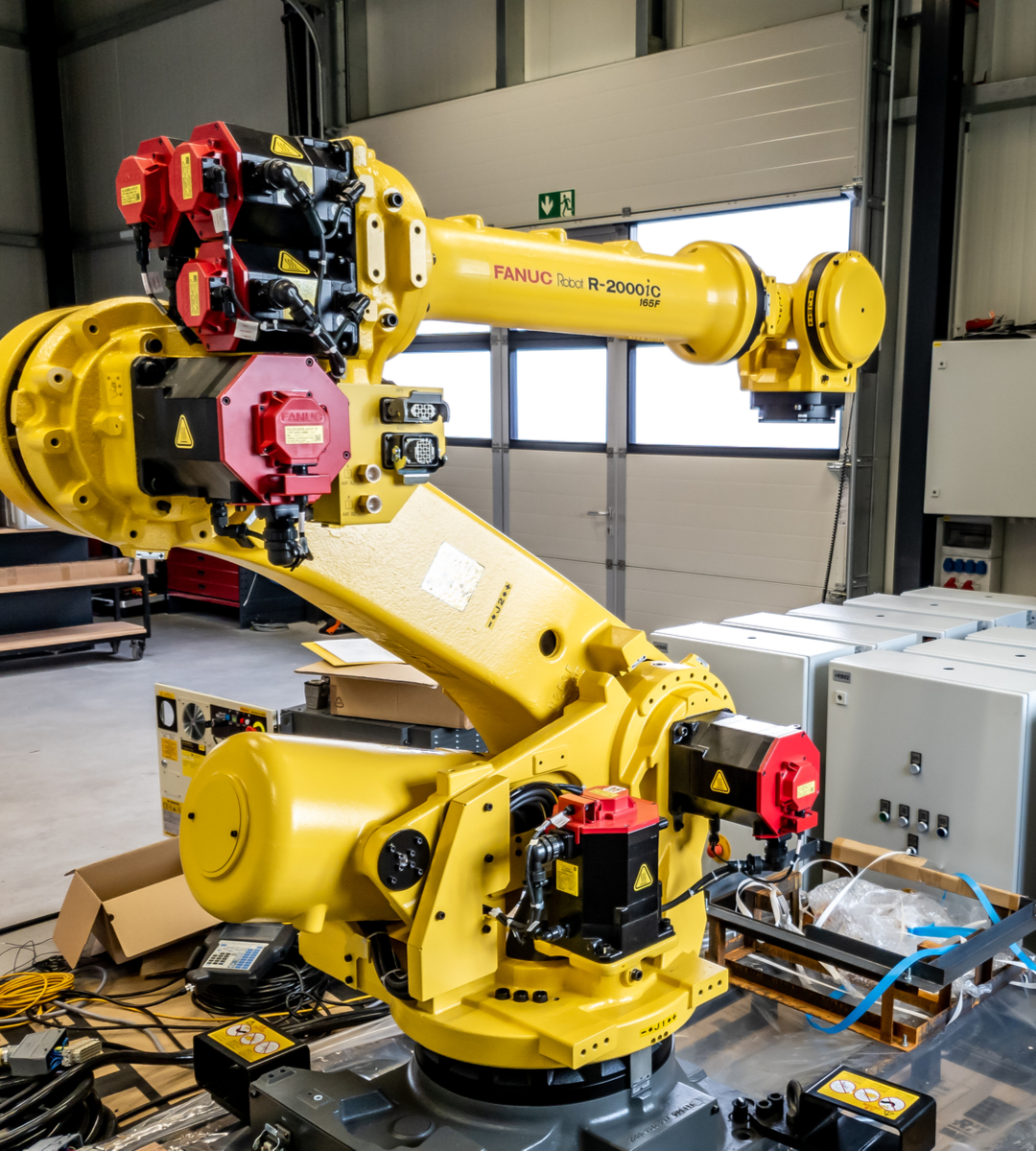

2. FANUC

Secondly, FANUC hails from Japan and is famous for robust industrial robots. Indeed, their signature yellow robotic arms populate factories worldwide. Specifically, FANUC specializes in CNC machinery, robotics, and factory automation systems. Consequently, they provide comprehensive solutions for numerous manufacturing applications.

Moreover, FANUC’s robots feature durable components that withstand heavy-duty operations. Indeed, they offer high payload capacities for tasks like welding and painting. Additionally, FANUC’s motion controllers enable synchronized multi-axis movement. Furthermore, their AI algorithms optimize resource allocation and predict maintenance needs.

Hence, FANUC holds a large market share in industrial robotics. Specifically, manufacturers trust their reliability, scalability, and continuous innovation. Therefore, FANUC remains a top choice for businesses aiming to expand automation efforts.

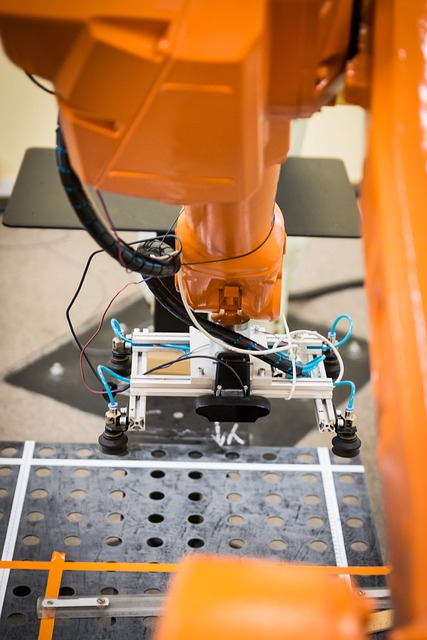

3. KUKA

Thirdly, KUKA is a German-based leader in robotics and system engineering. Indeed, they are particularly known in the automotive sector. Moreover, KUKA robotic arms handle welding, painting, and assembly tasks. Consequently, they now also serve aerospace, consumer goods, and other industries.

Additionally, KUKA offers heavy-payload robots with capacities up to 1,300 kg. Indeed, their KUKA Robot Language streamlines programming for complex tasks. Furthermore, mobile robotics solutions help businesses achieve flexible intralogistics. Moreover, their digital twin technology aids in system simulation and predictive maintenance.

Hence, KUKA’s engineering prowess underpins their success across diverse industries. Specifically, their robust hardware and Industry 4.0-friendly solutions guarantee future-proof operations. Thus, many global manufacturers rely on KUKA for seamless automation.

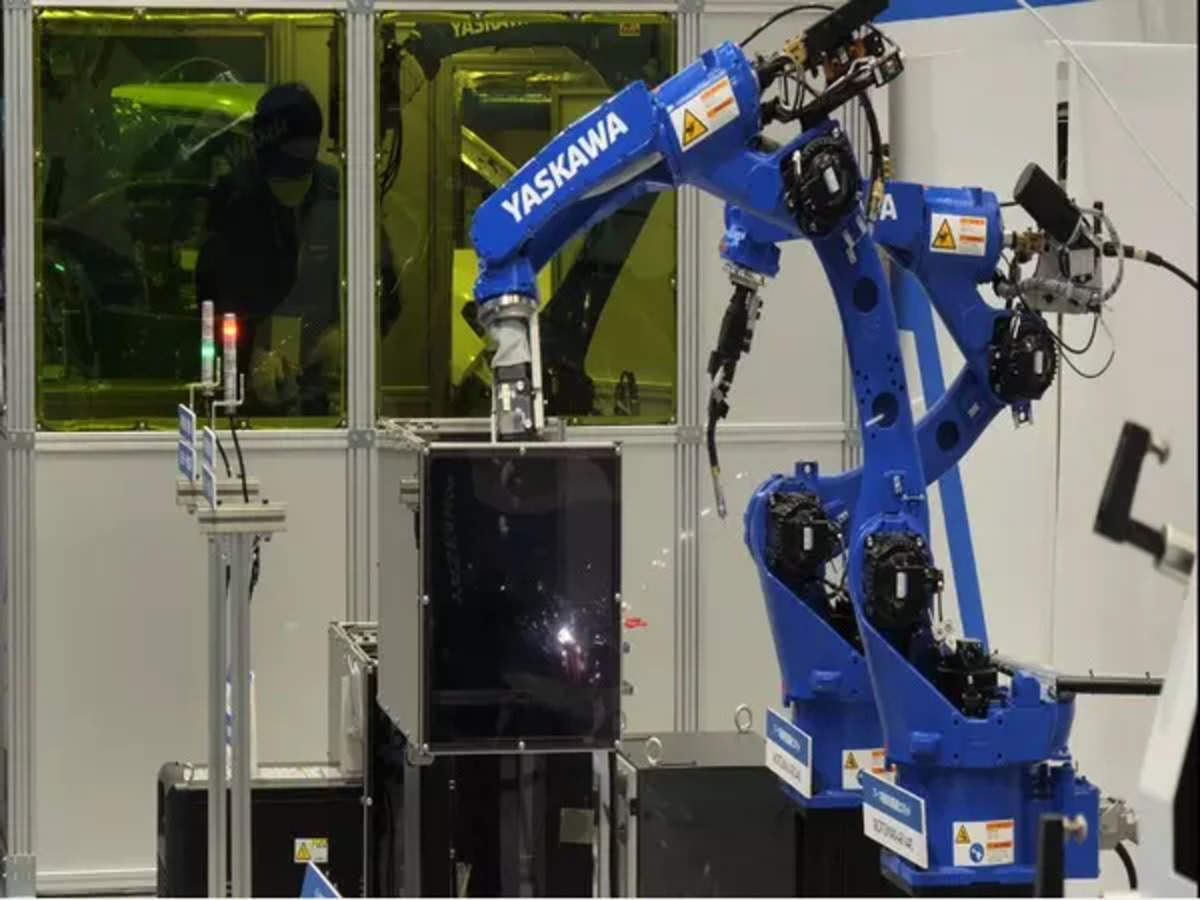

4. Yaskawa Electric Corporation

Fourthly, Yaskawa Electric Corporation is a Japanese leader in motion control and robotics. Indeed, their Motoman robots are widely recognized for speed and precision. Consequently, they also excel in AC drives, servomotors, and advanced automation tools. Moreover, Yaskawa solutions serve packaging, food processing, and pharmaceutical industries.

Additionally, many Yaskawa robots feature compact footprints that save valuable floor space. Indeed, their multi-robot synchronization boosts throughput on complex assembly lines. Furthermore, high-speed pick-and-place operations maintain precision and reduce cycle times. Meanwhile, advanced safety standards ensure compliant human-robot collaboration.

As a result, Yaskawa meets demands from small businesses and large enterprises alike. Specifically, their solutions adapt to varying production volumes and budgets. Consequently, Yaskawa remains a favorite for companies seeking scalable automation.

5. Rockwell Automation

Lastly, Rockwell Automation is an American multinational renowned for industrial control systems. Indeed, they champion digital transformation through robust hardware and software. Additionally, their Allen-Bradley PLCs set the standard for reliability and real-time control. Consequently, Rockwell’s platforms integrate data analytics and IoT capabilities.

Moreover, Rockwell’s Integrated Architecture® merges control, visualization, and networking in one environment. Indeed, their FactoryTalk® suite offers advanced analytics and remote monitoring. Likewise, safety features span multiple layers, protecting workers and assets. Meanwhile, strong IT/OT convergence simplifies enterprise-wide automation.

As a result, Rockwell Automation enables smart manufacturing for diverse industries. Specifically, their solutions unite operational data and advanced digital tools. Consequently, many global enterprises select Rockwell as a strategic automation ally.

Comparing the Best Automation Companies

Moreover, the following table compares crucial aspects of these leading providers. Indeed, it highlights their primary focus, notable robotics, core software, and unique advantages.

| Company | Primary Focus | Notable Robotics Series | Software Ecosystem | Key Differentiator |

|---|---|---|---|---|

| ABB | Industrial Automation & Robotics | IRB, YuMi Cobots | RobotWare, RobotStudio, Ability™ | Collaborative robots, IoT integration |

| FANUC | CNC & Industrial Robots | LR Mate, M Series | iRVision, AI Analytics | CNC expertise, robust AI |

| KUKA | Robotics & System Engineering | KR Series | KRL, KUKA.WorkVisual | Heavy payload, mobile robotics |

| Yaskawa | Robotics & Motion Control | Motoman Series | YRC Controller, MotoSim | High-speed operations, multi-robot sync |

| Rockwell | Industrial Control Systems | N/A (Partnered Robots) | Allen-Bradley, FactoryTalk® | Integrated Architecture®, IT/OT convergence |

Technical and Industrial Considerations

However, choosing the right automation partner requires evaluating multiple factors. Indeed, payload, reach, and cycle time can determine operational feasibility. Furthermore, software integration ensures smooth deployment and reduced downtime. Moreover, safety features and regulatory compliance protect workers and equipment. Consequently, providers with strong technical support can shorten learning curves. Meanwhile, scalability and upgrade paths remain vital for long-term growth.

Future Trends in Automation and Robotics

Indeed, collaborative robots now thrive in settings requiring flexible operations. Moreover, digital twins allow predictive maintenance without interrupting live production. Additionally, edge computing and IoT integration enable faster data processing and reduced latency. Consequently, AI-driven analytics improve quality checks and resource management. Thus, these advancements will redefine global manufacturing and service sectors.

Conclusion

Certainly, the best automation companies continue to pioneer new solutions for diverse industries. Specifically, ABB, FANUC, KUKA, Yaskawa, and Rockwell Automation lead this ongoing transformation. Moreover, each offers unique strengths in robotics, software, and digital infrastructure. Consequently, businesses can choose a partner that aligns with their strategic goals. Indeed, careful consideration of technical requirements ensures maximum return on investment. Therefore, a future driven by automation and robotics promises heightened efficiency and enduring competitiveness.