6-axis robots, also known as 6 DOF robots, are revolutionizing automation. They offer flexibility, precision, and efficiency in industries like manufacturing, healthcare, and logistics. With six degrees of freedom (DOF), these robots can perform complex tasks with ease. In this article, we’ll explore the key features, applications, advantages, and challenges of 6-axis robots.

What Are 6-Axis Robots?

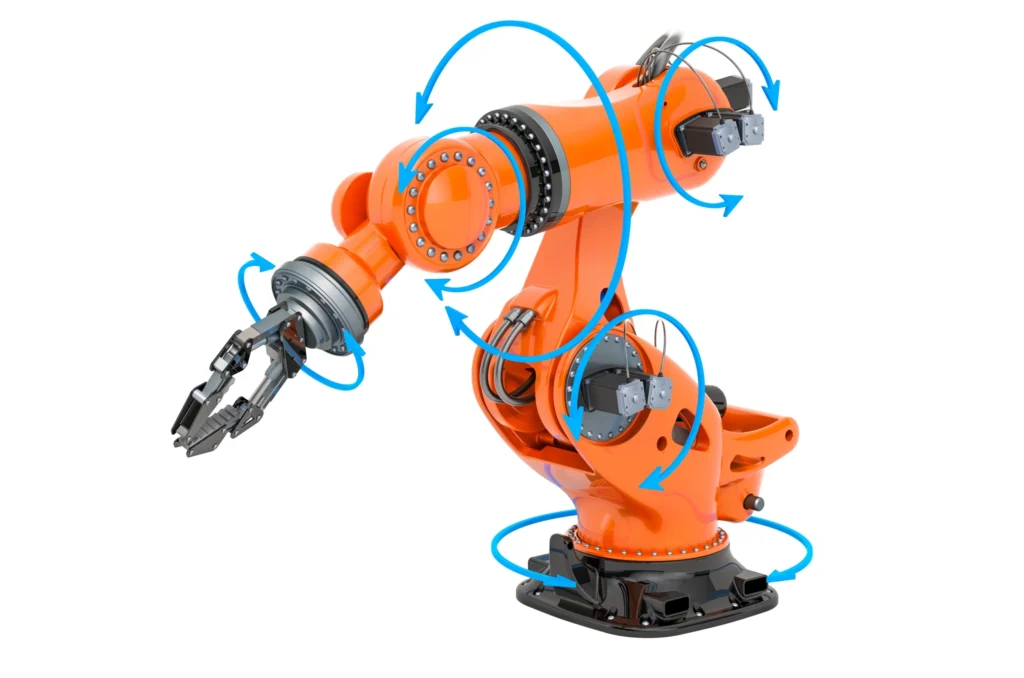

A 6-axis robot is an industrial robot with six degrees of freedom (DOF). It can move in six independent directions, mimicking a human arm’s movement. These robots use servo motors and controllers to execute precise tasks.

Degrees of Freedom Explained

The degrees of freedom (DOF) in a 6 DOF robot represent the different types of motion it can perform. The first axis, known as the base rotation, allows the robot to rotate around the vertical axis, giving it the ability to turn and face different directions. The second axis, the shoulder movement, enables the robot to move forward and backward, mimicking the motion of a human arm.

The third axis, elbow movement, allows the robot to extend and retract, further enhancing its range of motion. Moving to the wrist, the fourth axis, wrist pitch, enables the robot to move its wrist up and down. The fifth axis, wrist yaw, allows the robot to rotate its wrist side to side, offering additional flexibility. Finally, the sixth axis, wrist roll, enables the wrist to rotate around its own axis, completing the full range of movements that make 6 DOF robots highly versatile in performing complex tasks.

Applications of 6 DOF Robots

1. Manufacturing

In manufacturing, 6-axis robots streamline assembly line automation by efficiently assembling parts and components with high precision. They also perform welding and cutting tasks, offering consistent results and reducing human error. For material handling, these robots pick, move, and organize materials, optimizing workflow and increasing production speed.

2. Automotive Industry

In the automotive industry, 6-axis robots are widely used for painting car bodies, providing smooth, uniform coats that enhance quality and efficiency. These robots also excel at inspecting components, checking for defects and ensuring product standards. Additionally, they handle heavy parts with ease, moving large components without compromising safety or precision.

3. Healthcare

In healthcare, 6-axis robots play a key role in assisting in surgeries, offering high precision in delicate operations. They are also used in medical sample handling, ensuring safe, efficient transportation and storage of samples. Furthermore, these robots aid in pharmaceutical packaging, automating the process to meet high hygiene standards and reduce human error.

4. Logistics and Warehousing

This robot improves picking and placing items in warehouses, ensuring fast and accurate order fulfilment. They also enhance sorting and packing, organizing goods efficiently for shipping. In automating inventory management, robots can track stock levels and optimize storage, minimizing human intervention and increasing operational efficiency.

5. Aerospace

In the aerospace industry, these are essential for aircraft part assembly, offering precision when assembling complex structures. These robots also perform drilling and fastening tasks, ensuring accurate and secure connections in aircraft construction. Additionally, they handle composite materials, managing delicate components without causing damage during the manufacturing process.

Advantages of 6-Axis Robots

Exceptional Flexibility

A 6 DOF robot offers unparalleled freedom of movement in all directions, making it perfect for tasks requiring intricate and complex motions.

Unmatched Precision and Accuracy

Equipped with advanced sensors and AI, these robots achieve precision beyond human capabilities, minimizing errors and boosting overall productivity.

Space-Efficient Design

Unlike SCARA or Cartesian robots, these robots have a compact design, enabling them to operate efficiently in confined spaces without sacrificing performance.

Boosted Productivity

By automating repetitive tasks, these robots significantly accelerate production processes, working around the clock to deliver higher output and reduce operational costs.

Enhanced Workplace Safety

With the ability to handle hazardous materials and heavy loads, these robots reduce the risk of workplace injuries, safeguarding human workers from dangerous tasks.

Challenges of 6-Axis Robots

High Initial Investment

The cost of these robots can be significant, as they require sophisticated software, controllers, and ongoing maintenance. This high initial investment can be a barrier for smaller businesses with limited budgets.

Complex Programming

Programming this robot demands expertise in advanced robotics languages such as Python, C++, or Robot Operating System (ROS). This complexity can require specialized knowledge, making it difficult for companies to manage without skilled technicians.

Ongoing Maintenance and Repairs

Despite their durability, these robots require regular maintenance to keep running efficiently. Technical issues or system malfunctions can lead to costly downtime, impacting production schedules and overall efficiency.

Future of 6-Axis Robots

The future of 6 DOF robots looks promising. With advancements in AI, machine learning, and IoT, these robots are becoming smarter and more efficient. Collaborative robots (cobots) are also on the rise, allowing safer human-robot interaction.

Conclusion

6 DOF robots are shaping the future of automation. Their flexibility, precision, and efficiency make them a valuable asset in various industries. Despite some challenges, the benefits far outweigh the costs. As technology evolves, these robots will become even more powerful, accessible, and intelligent.

Businesses looking to stay competitive should consider investing in 6-axis robots for enhanced productivity and innovation.